Sublimation

Immerse Your Brand in Vibrancy with Thunder Bay's Sublimation Magic.

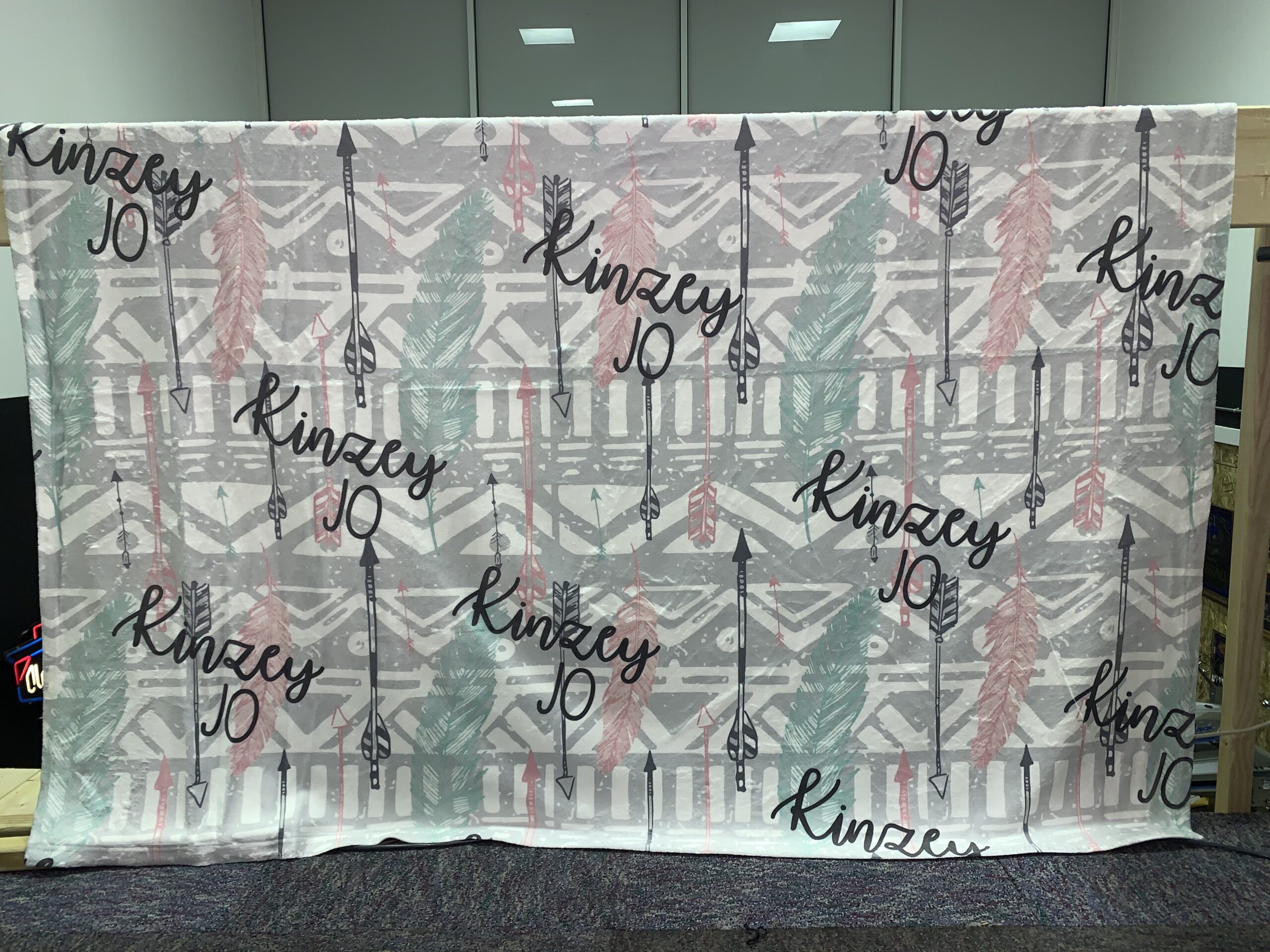

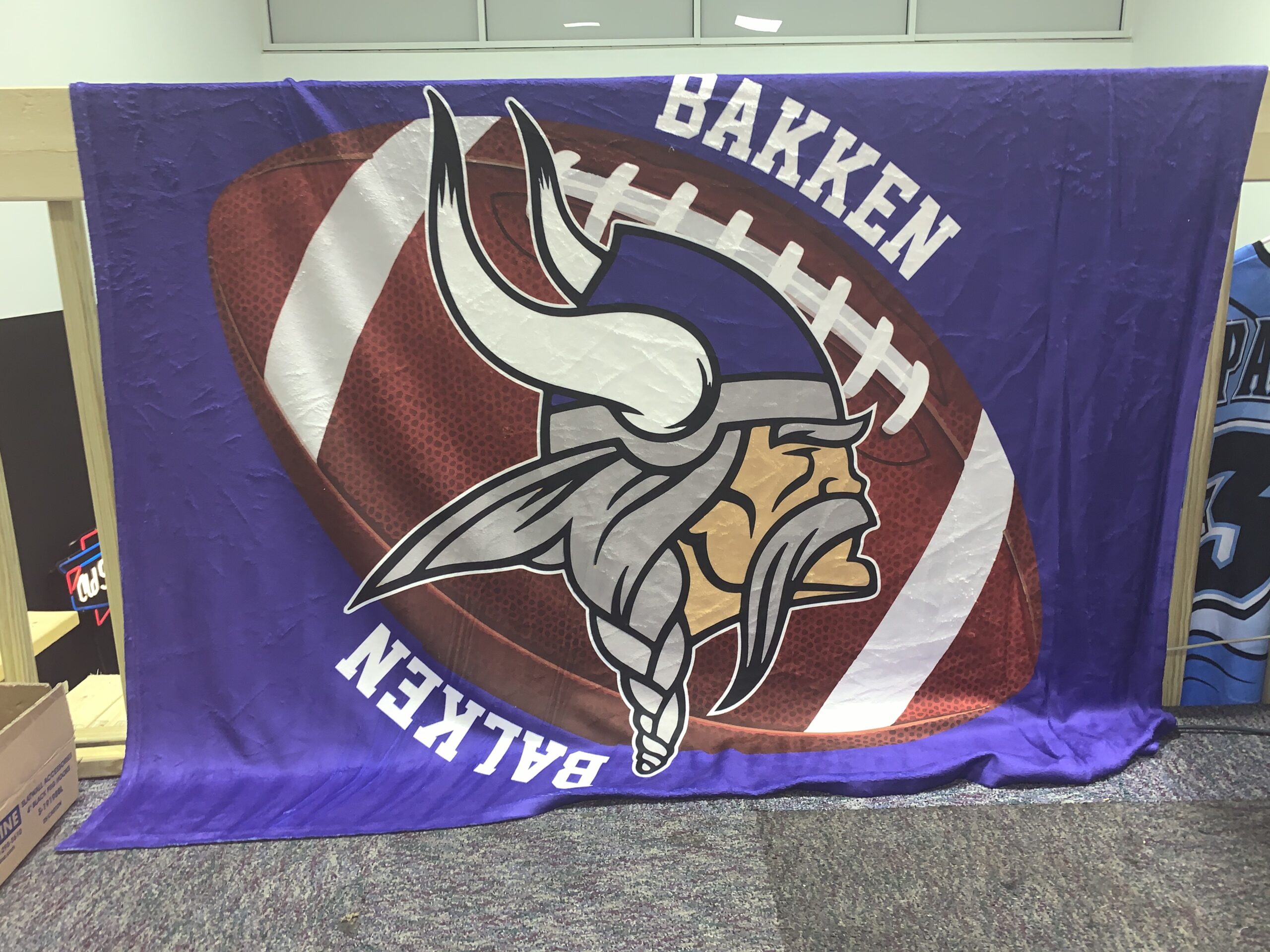

Sublimation is more than a printing method; it’s a way to infuse your brand with life and color. At Thunder Bay, we specialize in bringing your vision to reality through vibrant sublimation prints.

Why Thunder Bay for Sublimation?

Infinite Color Possibilities

Sublimation allows for a full spectrum of colors, ensuring your designs are as vibrant as your imagination.

Durability Meets Style

Enjoy prints that don't just look good but also withstand the test of time and wear.

Unique Design Opportunities

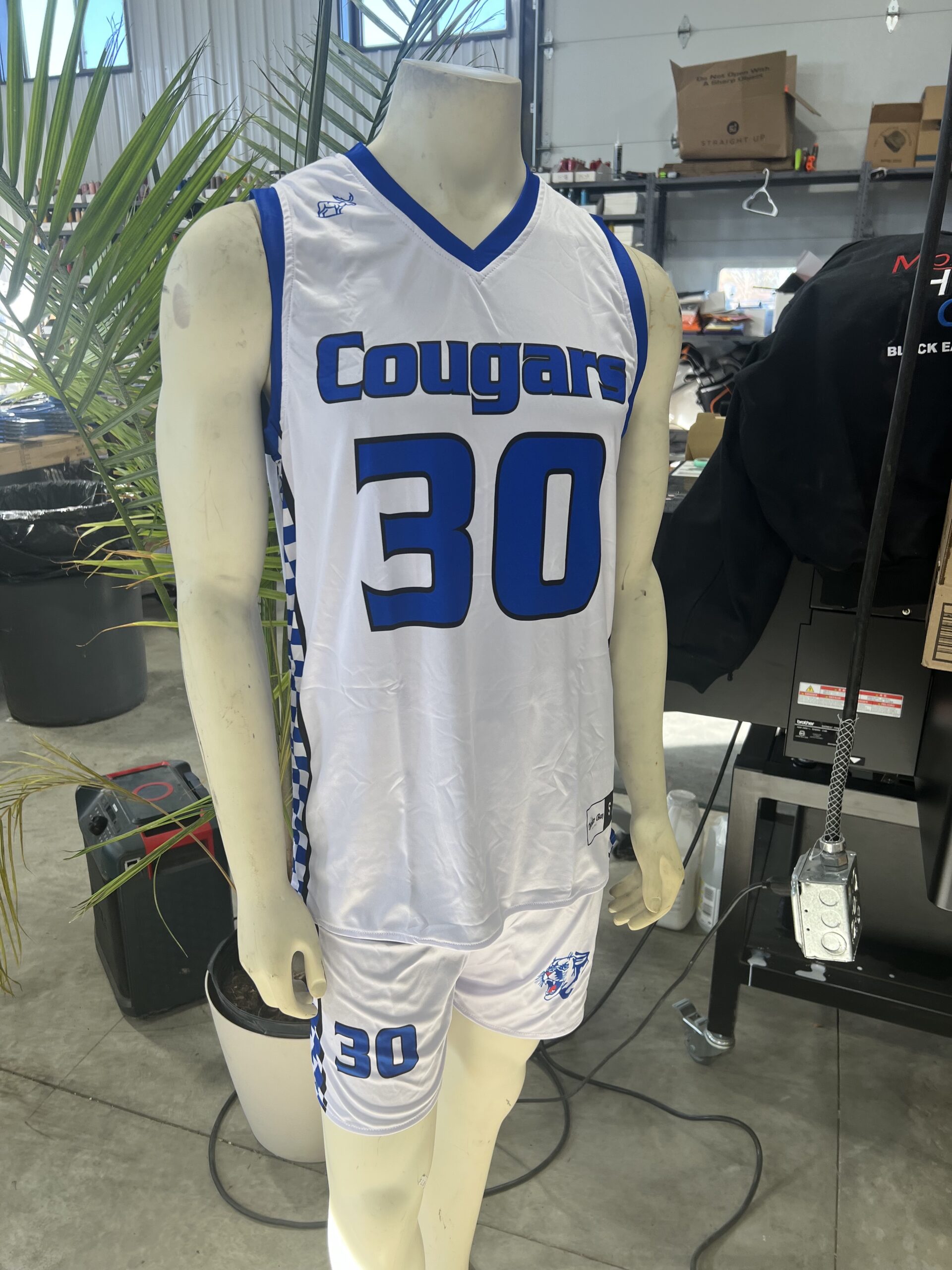

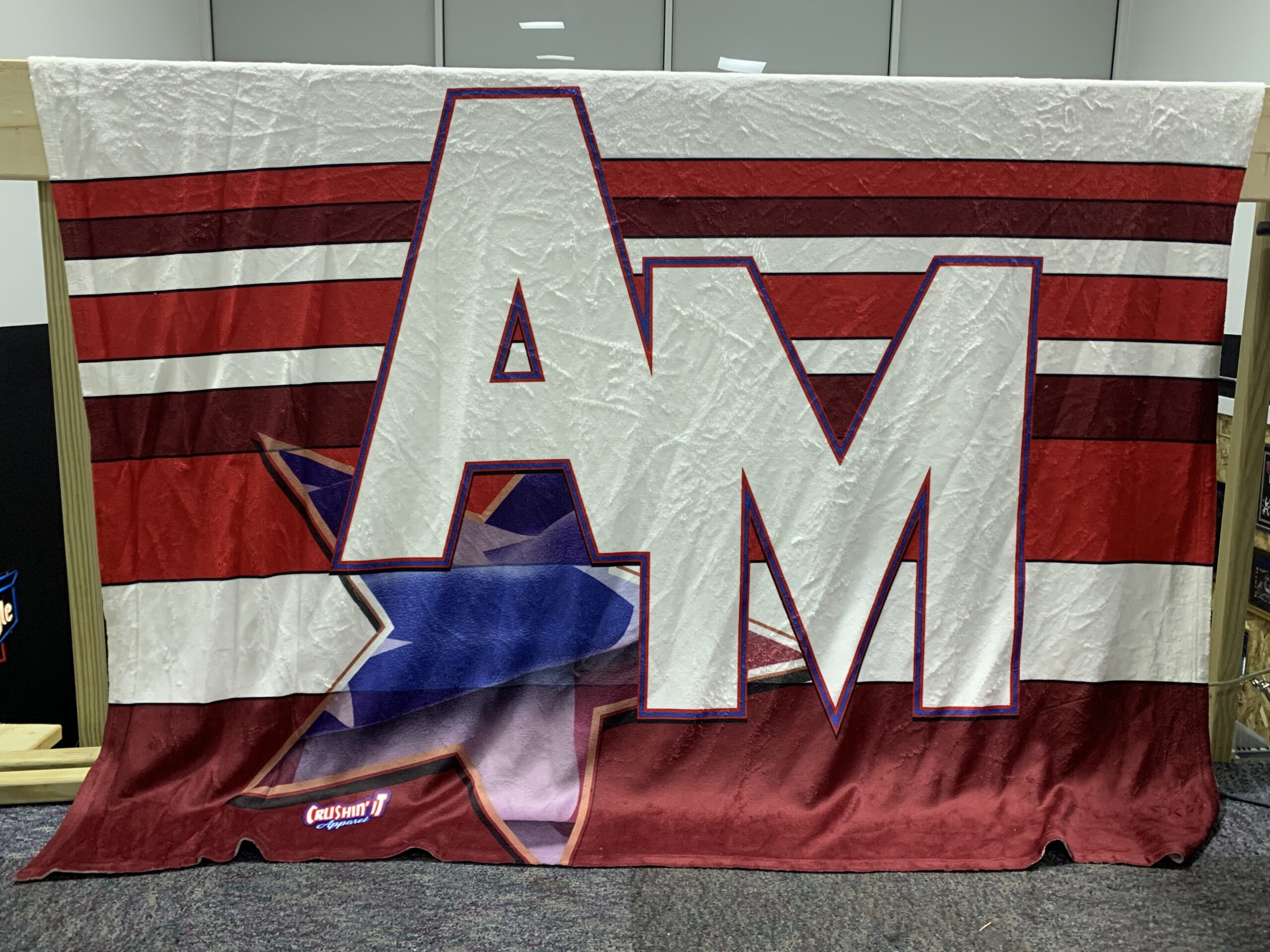

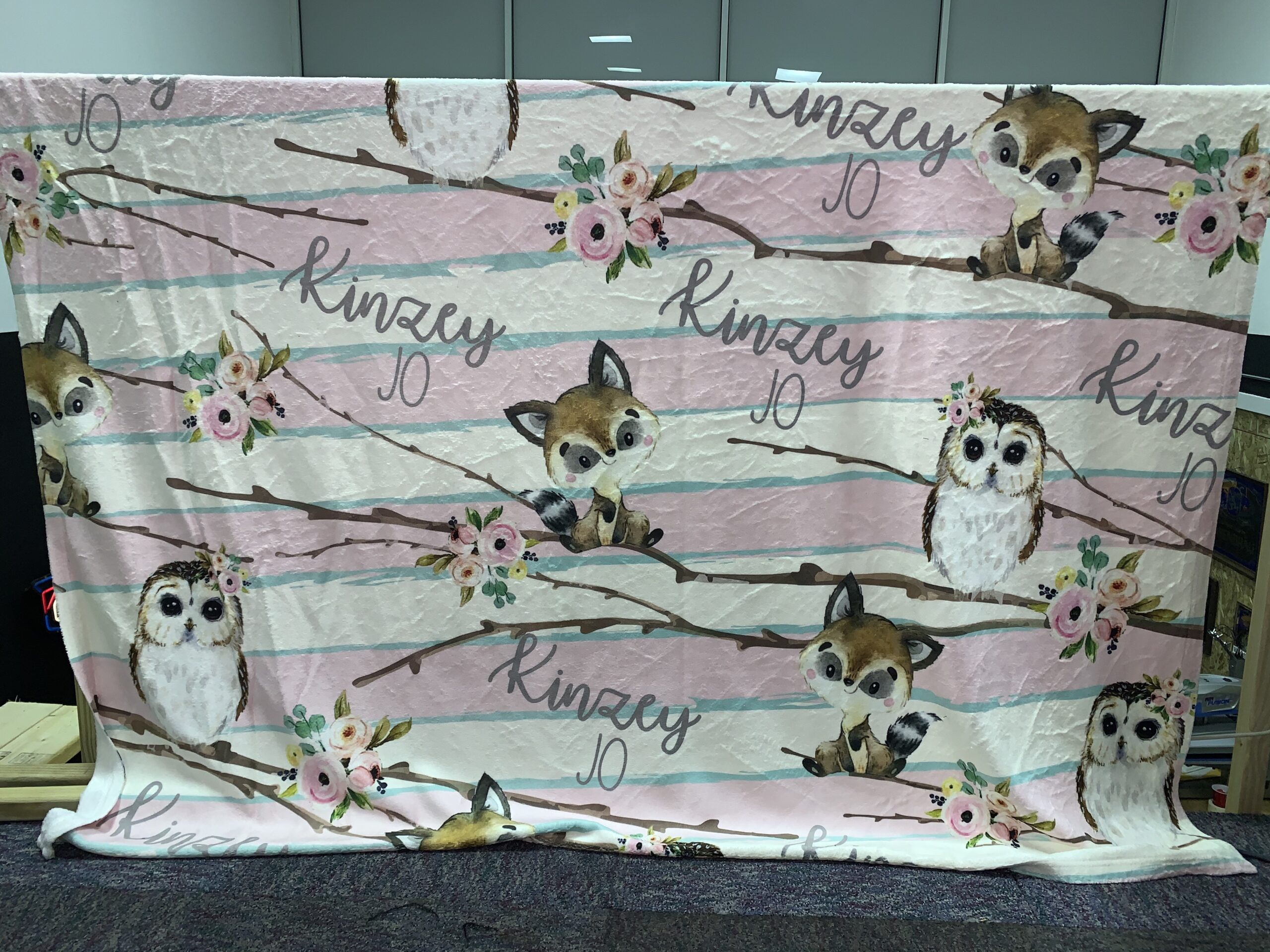

From all-over prints to intricate patterns, sublimation opens doors to unique design possibilities.

Uniforms, reversible Uniforms, shooting shirts, Hoodies, Socks, and more.

Steps Involve In It

Step 1

Conceptualization and Design

Initiate the sublimation process by conceptualizing your design. Collaborate with our skilled designers or provide your artwork. Ensure the design is high-resolution and tailored to your specific product dimensions.

Step 2

Printing the Design

Once the design is finalized, it's digitally printed onto a special sublimation paper using sublimation inks. These inks are unique because they have the ability to convert from a solid to a gas without passing through a liquid phase, making them ideal for sublimation.

Step 3

Preparing the Substrate

Prepare the substrate, typically made of polyester or polymer-coated items. These substrates are specifically chosen for their ability to absorb the sublimated ink. Ensure the substrate is clean and free from any contaminants to achieve the best results.

Step 4

Heat Press Transfer

Position the printed sublimation paper with the design facing down onto the substrate. Using a heat press machine, apply high temperature and pressure. The heat causes the sublimation inks on the paper to turn into gas, allowing them to penetrate the substrate's fibers and solidify, creating a permanent, full-color, high-resolution image.

Step 5

Cooling and Final Inspection

After the heat press transfer, allow the substrate to cool. This cooling process is crucial for the sublimation ink to fully set and bond with the substrate. Once cooled, inspect the item for quality, ensuring the colors are vibrant, and the design is sharp and well-defined.

Step 6

Finished Product

Your sublimated product is now ready. It boasts vibrant colors, exceptional detail, and durability. Whether it's apparel, promotional items, or personalized gifts, the sublimation process ensures a professional, long-lasting finish, making your designs stand out.